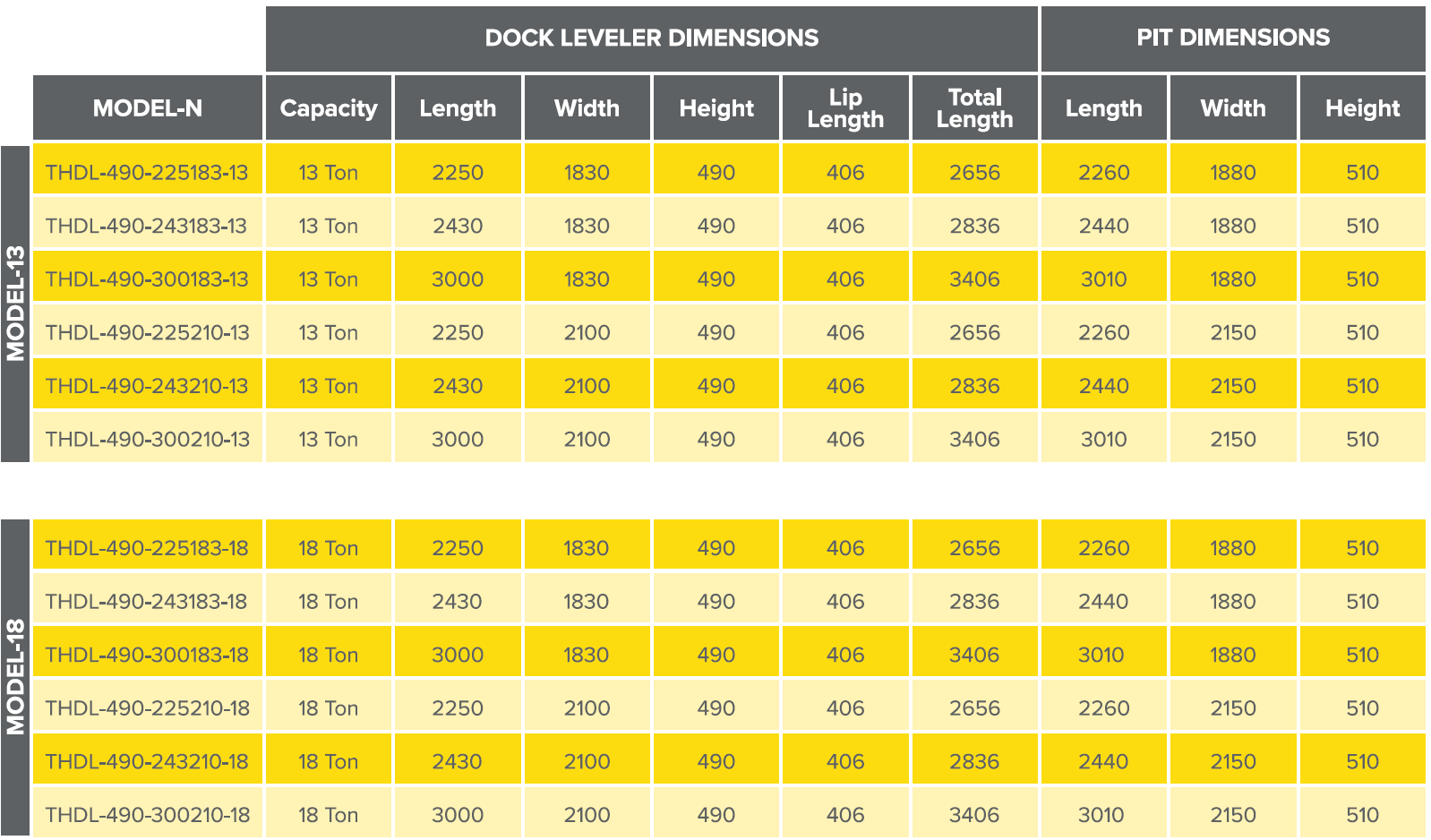

Dock Leveller

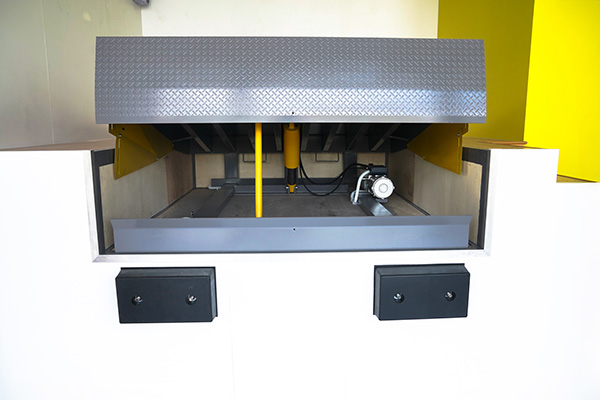

DOCK LEVELLER, a hydraulic platform specifically designed for installation at loading docks within warehouses and distribution centers. Its primary function is to bridge the height differential between the dock and truck beds, enabling safe and efficient loading and unloading operations. The leveller’s design accommodates various vehicle heights, enhancing work flow and reducing potential hazards.

By incorporating a dock leveller into loading operations, organizations can achieve several benefits: Operational Efficiency, Safety Enhancements, Reduced Equipment Damage and Lower Injury Risks.

Overall, the implementation of dock levellers contri- butes to optimized logistics operations and is crucial for maintaining safety standards in industrial environments.

Structure

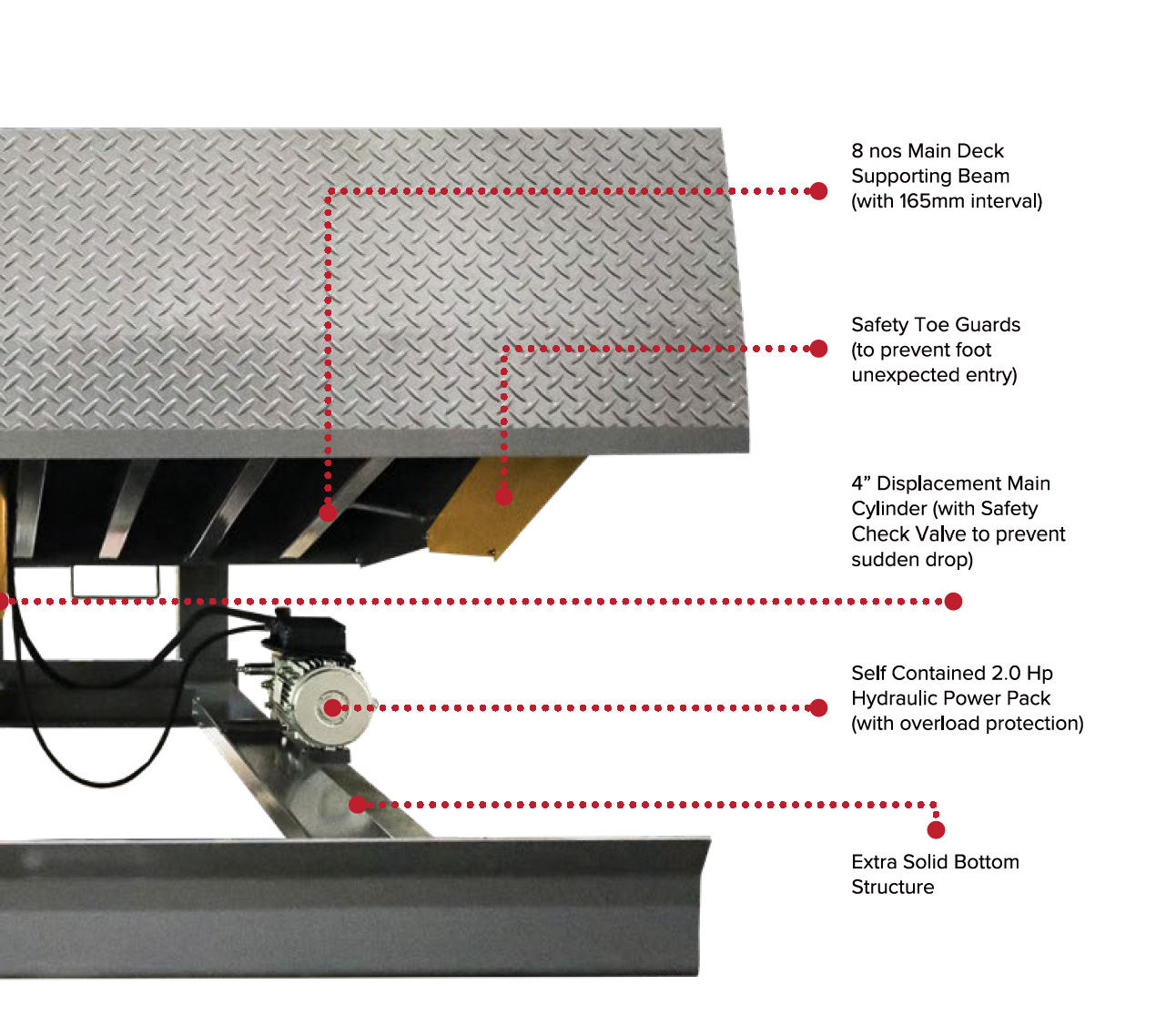

Sufficient Toe Guard

It is on the side of Dock Leveller to prevent worker’s toes from getting caught underneath the deck during loading and unloading operation.

Digid Support Structure

Strong support frame provides stability and load-bearing capacity for the entire Dock Leveller, it ensures that the platform remains secure during loading end unloading actvities.

Digid Base Beam

Main Base beam allow the cylinder to take the load when auto burst valve is activated.

Maintenance Bar

It is placed across the platform of the dock leveller, it prevents accidental lowering of the dock leveller while maintenance is in progress.

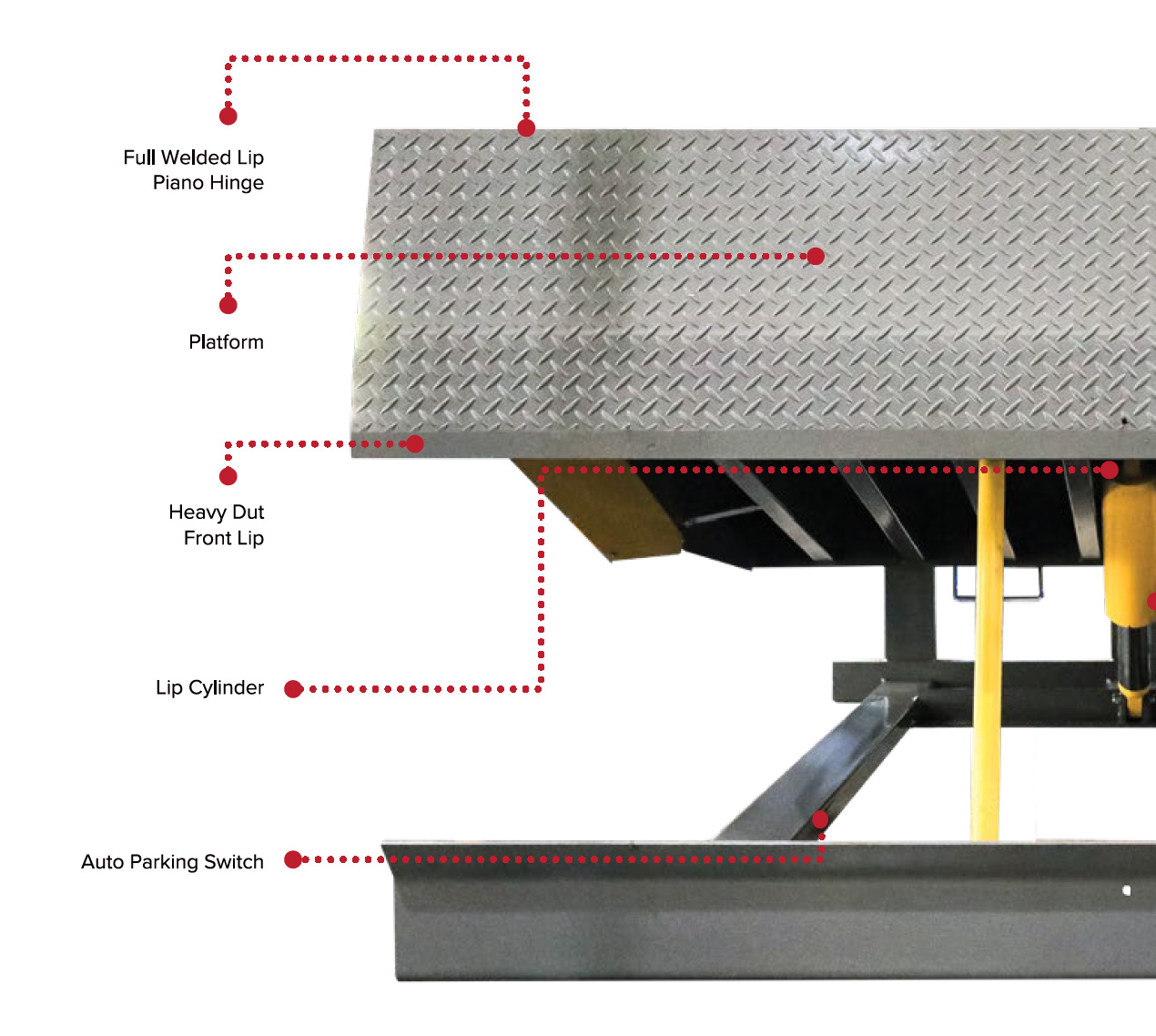

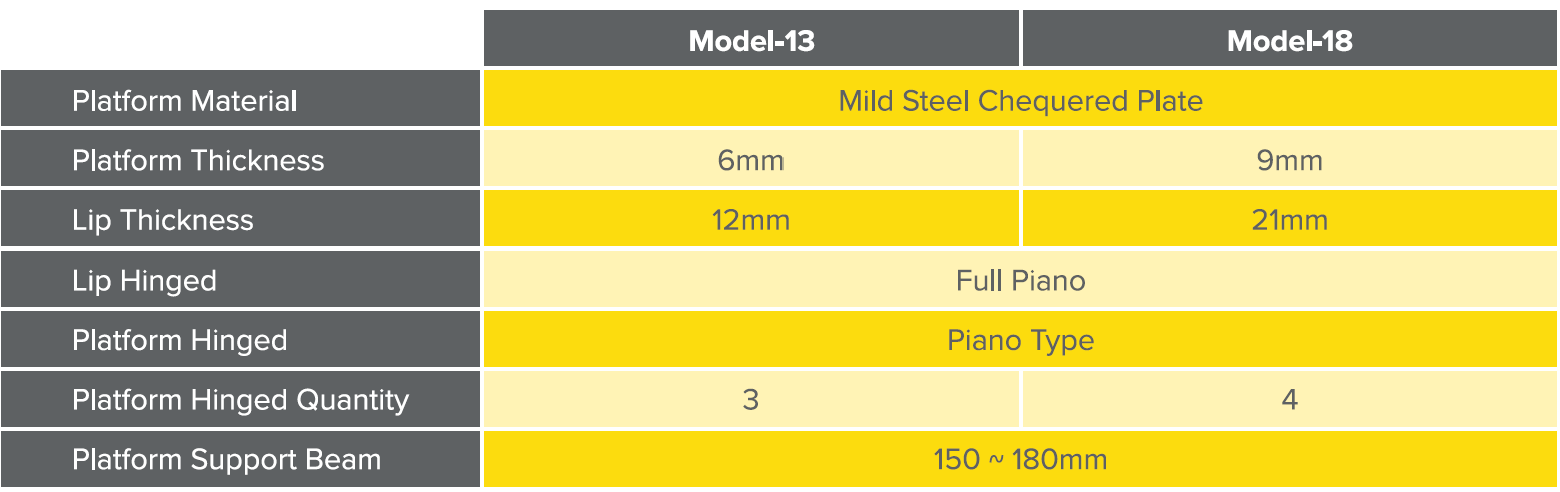

Heavy Duty Lips

12mm thickness Lip on dock leveller serve a critical purpose in ensuring safe and efficient loading and unloading operation.

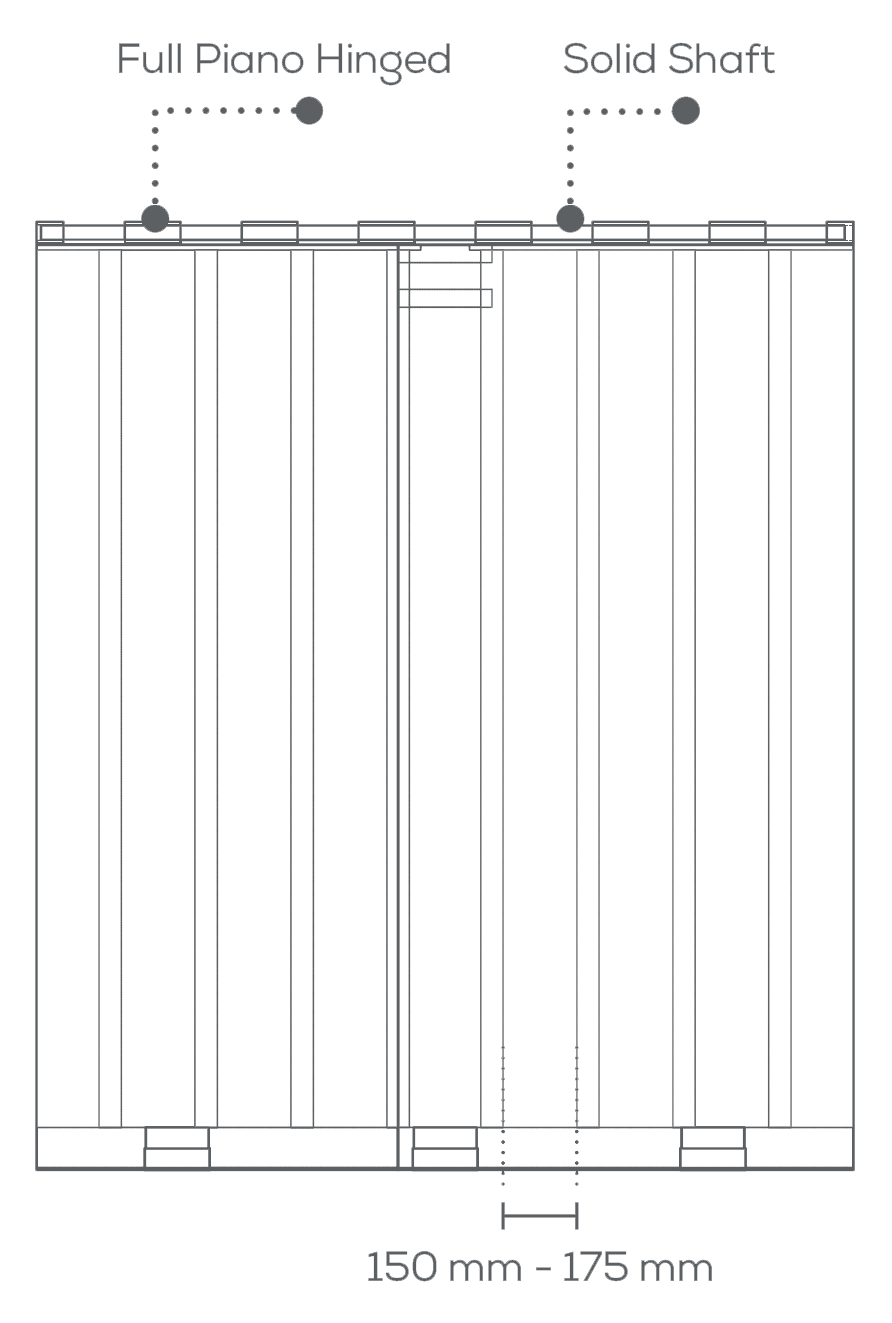

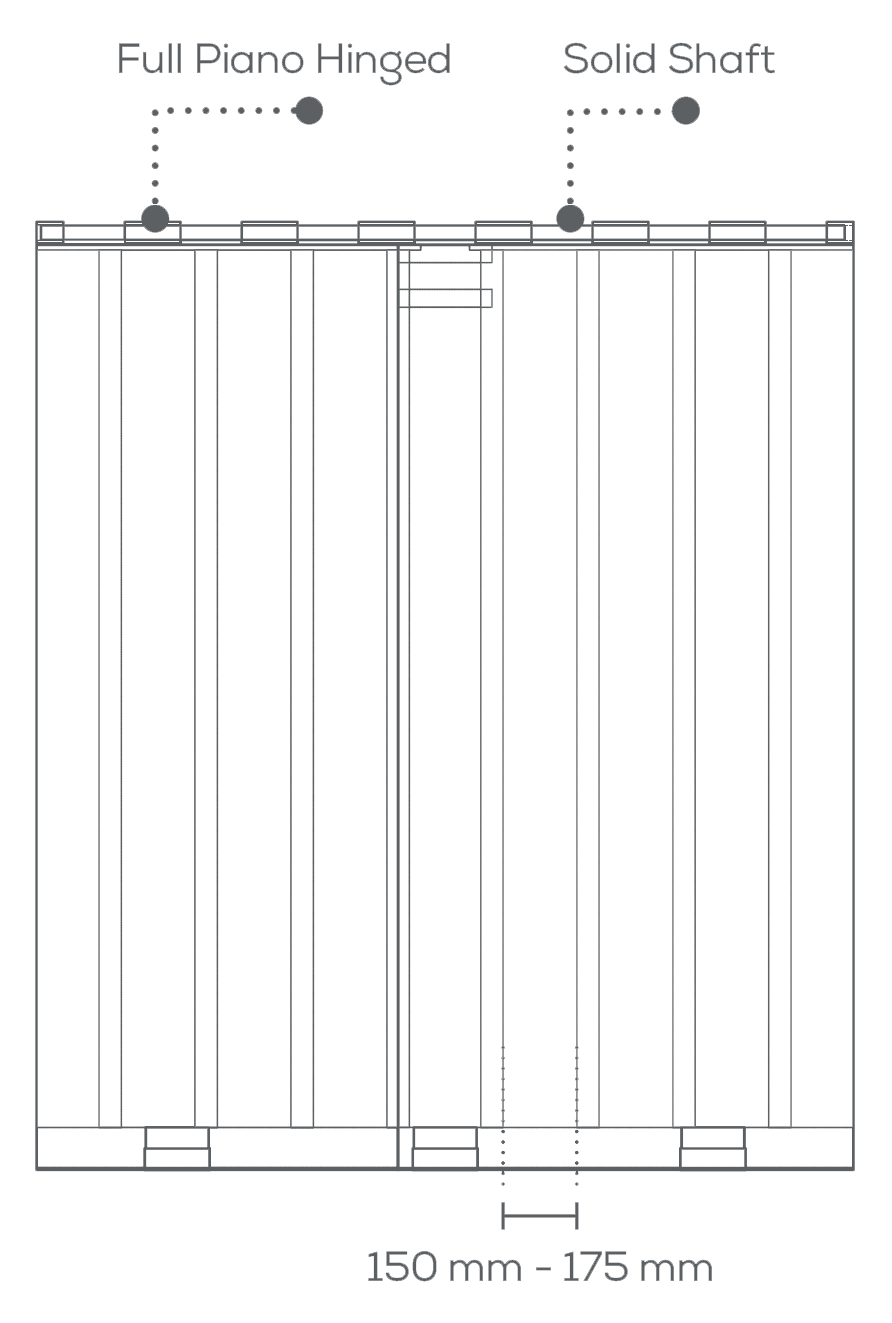

Rigid Platform

150mm Gap Platform : Typically constructed with high tensile steel for durability and strength to withstand heavy load.

Solid Piano Hinge

Continuous hinges that run the full width of the dock leveller platform, connecting the platform to the lip, compared to traditional multi-point hinges, piano hinges require less maintenance and offer better alignment over time. It provides smooth movement when the lip deploys and retracts, minimizing friction and the chance of mechanical jamming.

Hydraulic

Powerpack

2 HP Powerpack, ensure reliable performance and safety for dock leveller .

Low Operating Pressure

500psi Low-pressure system to ensure power pack long working life, also put less stress on seals, hose and others components

Pump Overload Protection

Safety feature designed to prevent damage to oil pumps by detecting and responding to conditions that could cause the motor or pump system to exceed its designed capacity. This feature is essential in Dock Leveller to ensure reliability, minimize downtime, and extend the life of the equipment.

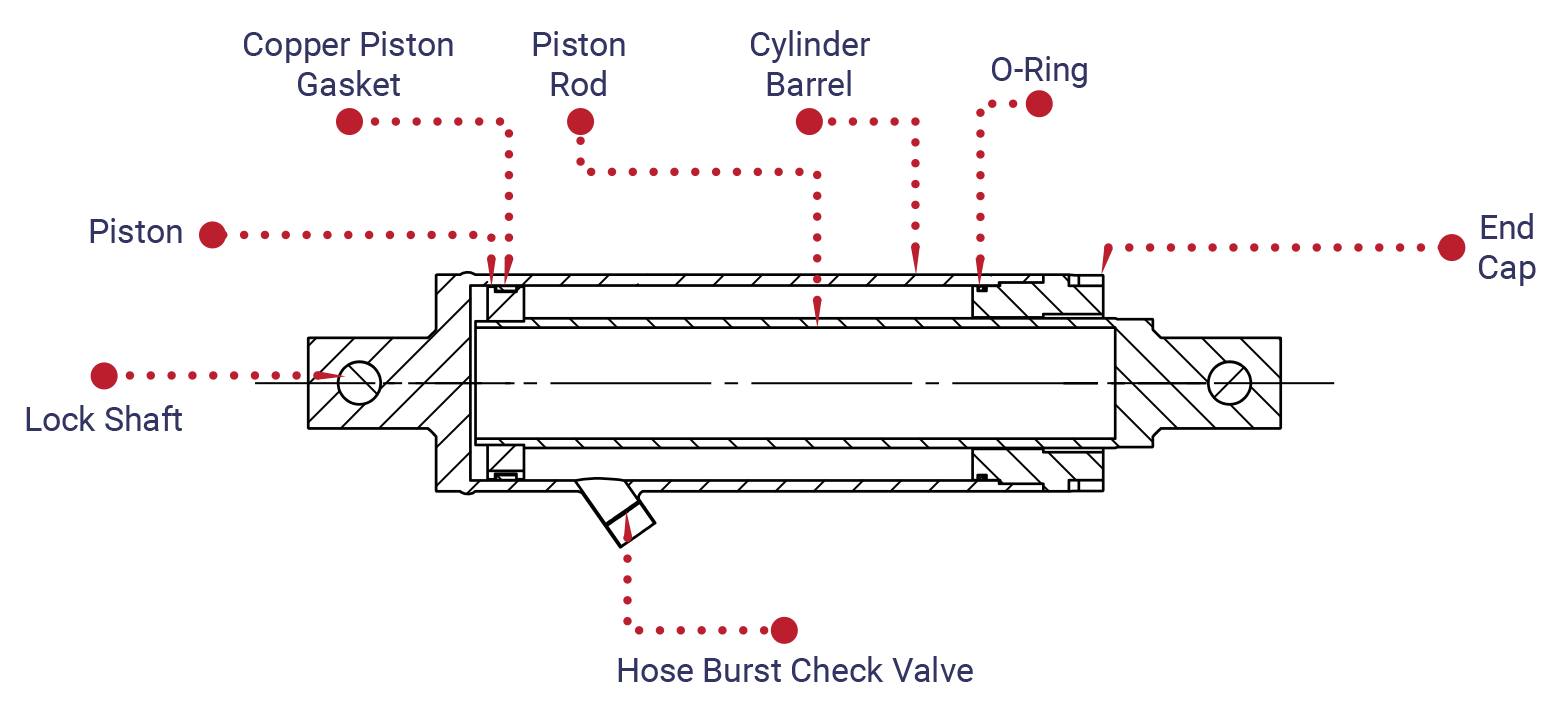

Cylinder with Hose Burst Check Valve

100mm bore cylinder is engineered to maintain optimal operation at 500 psi, ensuring extended component life span and minimized maintenance costs. The cylinder is integrated with a hose burst check valve, a critical safety feature designed to hold the platform securely in place. This valve activates automatically if the truck prematurely departs from the dock leveller, preventing unintended movement of the platform and ensuring operational safety.

Electrical

Electrical Emergency Stop

For holding platform position.

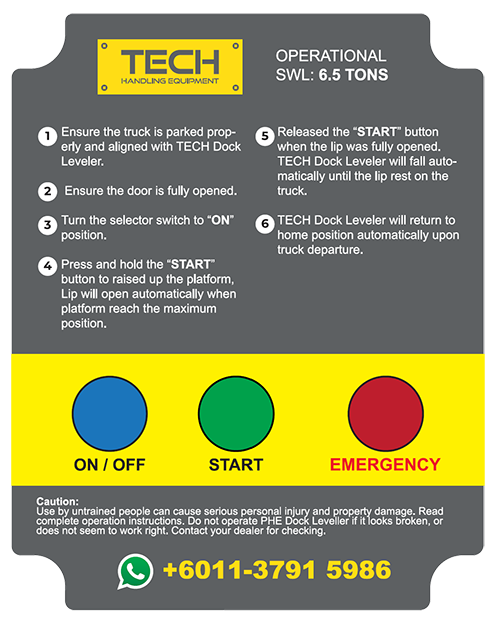

Full Auto Operating System

TECH dock leveller is engineered with a fully automated operation system, allowing for seamless control via a single push button. This design facilitates the lifing of the platform and the extension of the lip with minimal user intervention, enhancing operational efficiency and user convenience.

Auto Return System

The Auto Return System designed to ensure that the dock leveller platform consistently returns to a neutral position after each use. This feature is citical for maintaining safety for both forklift operators and workers in the vicinity, by ensuring that the platform remains in a stable, neutral position, the system reduces the likelihood of accidents, thereby protecting personnel and equipment from potential hazards associated with unintentional movement.

Low Control Voltage

Designed with low operating voltage systems enhance safely and efficiency in industial applications. Operating at lower voltages reduces the risk of electrical hazards and allows for safer operation in environments where moisture or other hazardous condi- tions may be present.

Accessories

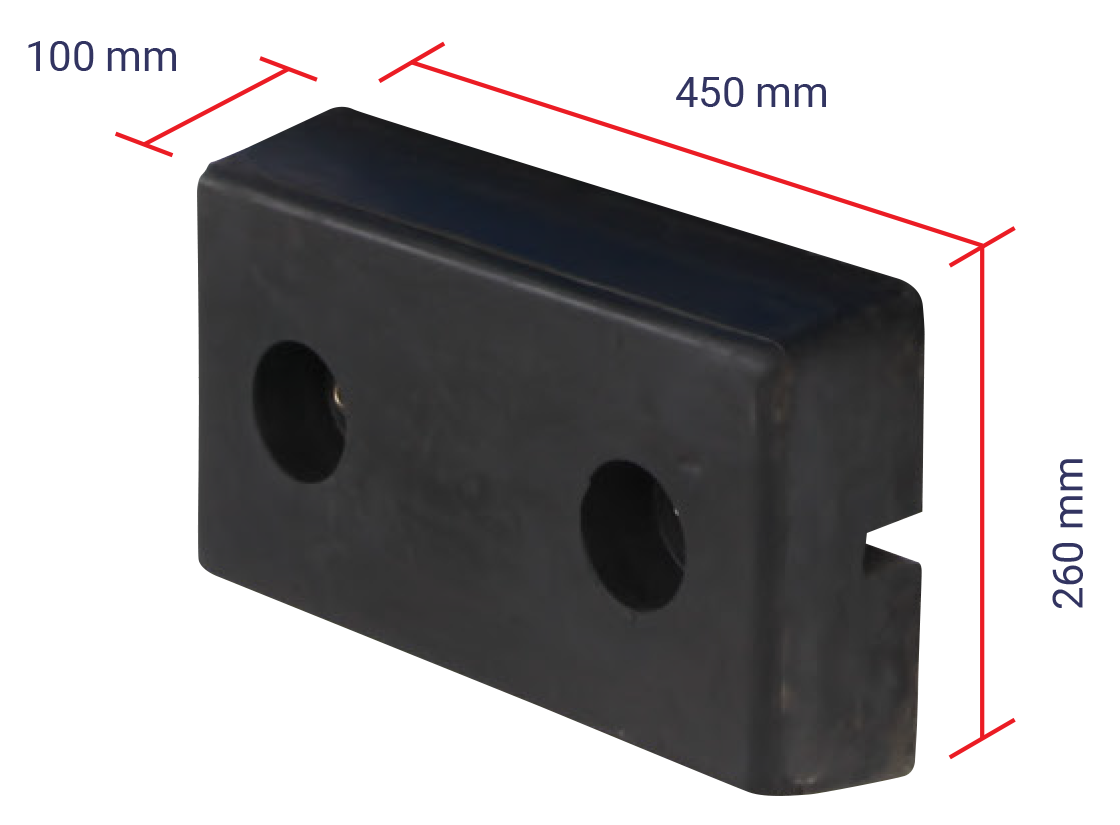

Rubber Bumper

Rubber bumpers for dock levellers are essential components used to protect both loading docks and vehicles during the loading and unloading process, our rubber bumper covers larger areas, offering more comprehensive protection.

DOCK LEVELER

Download Our Catalogue for More Details